Giving way

Give way means to slow down and, if necessary, stop in order to prevent a crash from happening.

You must always give way at a give way sign and check it's safe to continue. Give way signs are placed at intersections and other places where other vehicles have priority.

Remember, there are lots of situations on the road where you must give way even if there is no sign.

You need to give way if:

- the rules say that you must

- there's a give way or stop sign

- there are stop or give way lines on the road

- you're turning right across the path of an oncoming vehicle at an intersection

- you're turning left or right at a T-intersection

- you're moving onto a road from a driveway or land next to a road

- you're moving off from being stopped on the side of the road

- you're doing a U-turn

- you're turning left at an intersection with a 'left turn on red after stopping' sign.

Intersections

An intersection is where 2 or more roads meet, and includes where a slip lane meets a road.

A T-intersection is where 2 roads meet (whether or not at right angles) and one of the roads ends.

Giving way at intersections with 2 stop signs or give way signs

Giving way when there is a stop sign and a give way sign

A stop sign is not more powerful than a give way sign when giving way. When 2 drivers arrive at stop or give ways signs at the same time, the stop sign becomes the equivalent of a give way sign. Both vehicles must give way to other vehicles before they must give way to each other.

In this example, 2 vehicles are opposite each other at an intersection. Vehicle A (in white) has a give way sign. Vehicle B (in yellow) has a stop sign.

Vehicle A (white) must give way to Vehicle B (yellow) because it is turning right across the path of Vehicle B (yellow).

Giving way at intersections with 1 stop or give way sign

Giving way at a give way sign to an oncoming vehicle that is not at a stop sign or give way sign

You need to give way if you face a give way sign or a stop sign or if there are stop or give way lines on the road, even if the other driver, who is not facing a stop or give way sign, is turning right across your path.

In this example, 2 vehicles are opposite each other at an intersection. Vehicle B (in yellow) is turning right across the path of vehicle A (in white) who has a give way sign.

Vehicle A (white) must give way to vehicle B (yellow) because vehicle A has a give way sign.

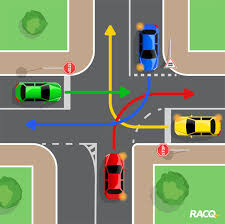

Giving way at uncontrolled crossroads

Giving way when turning at crossroads with no lights or signs

You must give way to vehicles on your right at an uncontrolled crossroad—this is a crossroad without any traffic lights, lines or signs.

In this example, Vehicle A (white) must give way to Vehicle B (yellow).

Giving way at a T-intersection

Giving way at a T-intersection

If you're driving on a road that ends at a T-intersection, you must give way to all vehicles—except those doing a U-turn—travelling on the road continuing through the intersection.

In this example, Vehicle A (white) must give way to Vehicle B (yellow).

Giving way when turning right

Giving way when turning right across the path of another car driving straight ahead

Giving way when turning right across the path of another car turning left

When turning right at an uncontrolled crossroad (without a slip lane), you must give way to vehicles coming from the opposite direction that are:

- driving straight ahead through the intersection

- turning left at the intersection.

In both examples, Vehicle B (yellow) must give way to Vehicle A (white).

Giving way when using slip lanes

Giving way on a slip lane

A slip lane is an area of road for vehicles turning left that is separated from other parts of the road by a painted island or traffic island.

If you're using a slip lane, you must give way to all traffic already on the road you're entering (except vehicles doing a U-turn).

Giving way to buses

Give way to buses sign

A bus is a vehicle that can carry 13 or more people (including the driver).

When you are driving in a built-up area and the speed limit is 70km/h or less, you must give way to a bus that displays a give way to buses sign on its back right-hand side, and is signalling to enter traffic from:

- a bus zone, bus stop or bus stop bay

- the shoulder of the road, or the left side of the road.

Remember to take special care around school buses, especially when their yellow lights are flashing. Watch out for children who may run across the road from in front or behind the bus.

Buses, like all other vehicles, are required to indicate for 5 seconds before moving off from a parked position, which includes a bus stop.

Giving way from a parked position

You must give way to all other vehicles and signal for at least 5 seconds when you drive on to the road from a parked position on the side of the road or in a median strip. You must stop signalling as soon as you have completed the manoeuvre.

Giving way when entering or leaving a road

Giving way when leaving a road

Giving way when entering a road

When you are entering or leaving a road from private property or a driveway, you must give way to pedestrians or bicycle and personal mobility device riders on the footpath or road.

You must also give way to any vehicles on the road you are entering. These rules apply whether you are driving forward or in reverse.

In both examples, Vehicle B (yellow) must give way to Vehicle A (white) and the pedestrian about to cross the driveway.

Giving way to pedestrians and bicycle or personal mobility device riders

Giving way to pedestrians when turning right

Giving way to pedestrians when turning left

You must give way to pedestrians and bicycle or personal mobility device riders on or entering a road you're turning into or entering. This includes pedestrians or bicycle and personal mobility device riders that are crossing on the green 'walk' signal at an intersection controlled with traffic lights, and you are turning into the road they are crossing.

In both examples, the white vehicle must give way to the yellow pedestrian crossing the road.

Giving way to pedestrian and bicycle rider

In this example, Vehicle A (white) must give way to bicycle rider B (yellow) and the pedestrian crossing the road.

If you are turning left using a slip lane, you must also give way to any pedestrian and bicycle or personal mobility device rider on or entering the slip lane.

Giving way to pedestrians on a slip lane

In this example, Vehicle A (orange) must give way to the pedestrian crossing the road.

14 Comment

34.01htt8xy698wnv2cbks1qfs52w@mail4u.fun

non et et eum consequatur cumque sed omnis. nihil asperiores praesentium vel quas assumenda similique aut. eum veniam quia sunt nesciunt laborum commodi qui velit.

35.01htt8xy698wnv2cbks1qfs52w@mail4u.run

ea corporis inventore minus eum consectetur et recusandae alias nam minus ipsa sunt expedita. neque voluptatem ipsam rerum corporis reiciendis nihil aspernatur neque sunt et doloribus quo error et. di

Mancubus0agins

<a href="https://vibromera.eu/product/balanset-1/">portable balancer</a> <p>Welcome to the world of portable balancers with the Balanset-1A, an advanced device specifically designed for dynamic balancing and vibration analysis across a variety of industrial applications. This versatile tool is perfect for balancing rotors such as crushers, fans, mulchers, augers on combines, shafts, centrifuges, turbines, and much more. The portable balancer is engineered to deliver high precision and reliability, making it an essential instrument for various industries that rely on optimal rotor performance.</p> <p>The Balanset-1A is equipped with two measurement channels that facilitate dynamic balancing in two planes, which is crucial for achieving enhanced efficiency and reducing wear and tear on machinery. As a result, this portable balancer allows users to ensure operational excellence by minimizing vibration and improving the performance of mechanical systems.</p> <p>One of the standout features of the Balanset-1A is its comprehensive range of functionalities designed for rotor balancing and vibration analysis. The vibrometer mode accurately measures rotational speed (RPM), providing vital information for monitoring and maintaining equipment. Additionally, it determines the phase angle of vibration signals, allowing for precise analytical insights into rotor dynamics.</p> <p>Moreover, the Balanset-1A offers various modes for balancing, including single-plane balancing and two-plane balancing. This functionality enables users to conduct dynamic balancing effectively, addressing imbalances that may otherwise compromise equipment performance. The polar graph visualization tool enables users to accurately position weights, thereby facilitating an effortless correction of imbalances.</p> <p>The device also retains the last session data, making it convenient for users to resume their previous balancing sessions without starting from scratch. With its tolerance calculator based on ISO 1940, users can compute acceptable balancing tolerances to ensure compliance with international standards.</p> <p>For grinding applications, the Balanset-1A utilizes three counterweights for balancing grinding wheels, further enhancing its versatility. To provide a thorough analysis, the device includes several charts, such as overall charts to visualize overall vibration, harmonic charts that indicate the presence and impact of harmonic frequencies, and spectrum charts for detailed frequency analysis.</p> <p>The Balanset-1A's archival feature allows for the storage and retrieval of past balancing sessions, which is invaluable for maintaining a comprehensive record of equipment performance. Additionally, it generates detailed reports outlining balancing outcomes, offering crucial insights for engineering and maintenance teams. This portable balancer is equally well-suited for serial production balancing, ensuring that manufacturers maintain peak performance throughout their production processes.</p> <p>This innovative device is designed with user-friendliness in mind, offering compatibility with both Imperial and Metric units. Hence, it caters to a diverse client base globally, ensuring convenience for various industrial applications. The specifications of the Balanset-1A are robust, featuring two vibration sensors (vibro accelerometers), an optical sensor (laser tachometer), and a USB interface module for connecting to PC software.</p> <p>The software capabilities extend further, allowing users to measure vibration, track phase angles, and calculate both the value and angle of the correction mass required for balancing. This high level of functionality ensures that users can achieve optimal balancing results with ease.</p> <p>In terms of specifications, the Balanset-1A can accommodate a wide range of operational parameters. For instance, it can measure rotational speeds ranging from 250 to 90,000 RPM and monitor RMS vibration velocity within the scope of 0 to 80 mm/s. The device features a frequency range capable of addressing vibrations from 5 Hz to as high as 1000 Hz, ensuring comprehensive measurement capabilities.</p> <p>The accuracy of the device is noteworthy, with an absolute measurement error of RMS vibration velocity maintained at ±(0.1 + 0.1*Vi), where Vi represents the measured RMS vibration velocity. Additionally, the phase shift measurements have tolerances within ±2 degrees, ensuring that the balancer delivers precise analytics critical for operational success.</p> <p>Lightweight and portable, the Balanset-1A weighs just 4 kg, making it easy to transport and use in various settings. This convenience means that technicians and engineers can quickly set up the device on site, minimizing downtime and maintaining productivity within their operations.</p> <p>Purchasing the Balanset-1A is a straightforward process; it is available for €1,751.00, reflecting the advanced technology and versatile capabilities that come with the portable balancer. Customers have the opportunity to add a range of essential components to their order, including vibration sensors, optical sensors, and magnetic stands, enhancing the device's functionality according to specific applications.</p> <p>In summary, the Balanset-1A portable balancer stands out as a remarkable tool that promises efficiency, precision, and reliability in vibration management and rotor balancing. Its advanced features, user-friendly design, and applicability across numerous industries make it an invaluable asset for anyone seeking top-tier performance in rotor dynamics and vibration analysis. Whatever your industrial balancing needs may be, consider the Balanset-1A to achieve optimal results and ensure the longevity of your machinery.</p>

Jeremyacity

<a href="https://vibromera.eu/example/dynamic-shaft-balancing-instruction/">static balancing</a> <div> <h1>Understanding Static Balancing</h1> <p>When it comes to maintaining rotating machinery, understanding the principle of static balancing is essential. Static balancing focuses on correcting the imbalance of a rotor when it is not in motion. In many machines, especially those involving rotors like fans, turbines, and various agricultural equipment, achieving static balance is crucial for preventing early wear and tear, as well as ensuring operational efficiency.</p> <h2>What is Static Balancing?</h2> <p>Static balancing refers to the condition where the center of gravity of a stationary rotor aligns with its axis of rotation. In simpler terms, it means that the weight is evenly distributed around the rotor. If the rotor has a "heavy point" due to uneven mass distribution, that point will gravitate downward due to gravity when the rotor is at rest. This situation leads to static imbalance.</p> <h2>Why is Static Balancing Important?</h2> <p>Static balancing is critical for narrow disk-shaped rotors, which can be found in various applications, from cooling fans to agricultural machinery. An unbalanced rotor can cause excessive vibrations, which can lead to machinery damage, increased energy consumption, and operational inefficiencies. By achieving static balance, we eliminate the uneven distribution of mass, reducing vibrations that can create noise and potentially harm the machinery over time.</p> <h2>How to Achieve Static Balancing</h2> <p>The process of static balancing involves adding or removing mass at strategic locations on the rotor until the heavy point is aligned with the axis of rotation. There are several steps involved in achieving static balance:</p> <ul> <li><strong>Initial Measurement:</strong> Use vibration sensors to assess the rotor's current state. This helps establish a baseline from which corrections can be made.</li> <li><strong>Adding or Removing Mass:</strong> Depending on the measurements, weights are either added or removed from specific points on the rotor. The goal is to place mass such that all points of the rotor become evenly weighted.</li> <li><strong>Verification:</strong> Once corrective weights are installed, the machine should be tested again to check if vibration levels have decreased, thus confirming static balance.</li> </ul> <h2>Static vs. Dynamic Balance</h2> <p>It's essential to differentiate between static and dynamic balance. Static imbalance, as described, occurs when the rotor is stationary and there are differences in weight distribution. Dynamic imbalance, however, occurs when the rotor is in motion and involves multiple planes of imbalance leading to additional forces during rotation. While static balancing deals with correction in one plane, dynamic balancing requires analysis in two or more planes, accounting for more complex vibration dynamics.</p> <h2>Real-World Applications of Static Balancing</h2> <p>Static balancing is utilized across various industries. For instance:</p> <ul> <li><strong>Manufacturing:</strong> Machinery used in manufacturing processes often requires static balancing to reduce wear and improve efficiency.</li> <li><strong>Agriculture:</strong> Equipment like mulchers and augers on combines benefit from static balancing to ensure even operation and reduced strain on structural components.</li> <li><strong>HVAC Systems:</strong> Fans and blowers that undergo static balancing operate more smoothly, which lowers noise levels and prolongs equipment life.</li> </ul> <h2>Tools for Static Balancing</h2> <p>To achieve effective static balancing, several tools are necessary:</p> <ul> <li><strong>Portable Balancer:</strong> Handy devices can measure vibrations and indicate necessary adjustments.</li> <li><strong>Calibration Weights:</strong> These are used to fine-tune the mass distribution on the rotor.</li> <li><strong>Vibration Sensors:</strong> Essential for monitoring how changes in weight affect the rotor's balance.</li> </ul> <h2>Conclusion</h2> <p>In conclusion, static balancing is a vital practice for ensuring the longevity and efficiency of machinery involving rotating parts. By understanding the principles of static balance, maintenance professionals can significantly reduce wear, prevent downtime, and enhance the overall performance of equipment. Proper static balancing techniques, combined with the right tools, lead to smoother operations and considerable cost savings in the long run.</p> <p>Through rigorous application of static balancing, industries can optimize their machinery performance, leading to enhanced productivity and reduced operational costs. Whether in manufacturing, agriculture, or HVAC, static balancing is a fundamental aspect of maintaining equipment health and functionality.</p> </div>

Molliserymn

<a href="https://vibromera.eu"><img src="https://vibromera.eu/wp-content/uploads/2021/11/БалкомКит-scaled.jpg" alt="Portable Balancer Balanset-1A" /></a> <a href="https://youtube.com/shorts/jO1-xniIPgg?si=yanUtnJQUMLydZ2R" target="_blank">Watch YouTube Short</a><br> <h1>Balanset-1A: A Revolutionary Rotor Balancing Device for Industrial Maintenance</h1> <p>In the world of industrial maintenance and repair, ensuring the optimal performance of machinery is paramount. One of the critical aspects of maintaining machinery is rotor balancing. The <strong>Balanset-1A</strong> is an innovative device designed to simplify and enhance the rotor balancing process, making it an essential tool for technicians and engineers alike.</p> <h2>Understanding Rotor Balancing</h2> <p>Rotor balancing is performed on technically sound mechanisms that are securely mounted in their designated positions. If a mechanism is found to be faulty, it must first be repaired, installed with functional bearings, and secured properly before balancing can take place. Additionally, rotors must be cleaned of any contaminants that could interfere with the balancing process.</p> <p>Before measurements are taken, vibration and phase sensors must be installed according to specific guidelines. Conducting a preliminary measurement in vibrometer mode is advisable. If the total vibration level approximately matches the rotational component, it indicates that rotor imbalance is likely the primary contributor to the vibration. Conversely, if the total vibration significantly exceeds the rotational component, a thorough inspection of the mechanism is warranted.</p> <h2>Key Features of Balanset-1A</h2> <ul> <li><strong>Compact and Portable:</strong> The Balanset-1A is designed for mobility, featuring a compact case that makes it easy to transport for on-site work.</li> <li><strong>Intuitive Software:</strong> The device connects to a laptop, offering user-friendly software with step-by-step instructions for setup and balancing.</li> <li><strong>Multi-functionality:</strong> Balanset-1A combines the functions of a vibrometer and a balancing device, allowing for comprehensive machinery diagnostics.</li> <li><strong>High Measurement Accuracy:</strong> The device offers phase measurement accuracy of В±1В° and vibration accuracy of В±5%, ensuring reliable results for various applications.</li> <li><strong>Adaptable Options:</strong> The Balanset-1A includes settings that can be tailored to specific tasks, such as displaying polar diagrams or calculating allowable imbalance based on ISO 1940 standards.</li> <li><strong>Easy to Learn and Use:</strong> No deep expertise in vibration diagnostics is required, making it accessible for users of all skill levels.</li> <li><strong>Support for Series Balancing:</strong> Ideal for mass production environments, it streamlines the balancing process for multiple identical rotors.</li> <li><strong>Cost-Effective:</strong> Priced at €1751, the Balanset-1A offers an excellent return on investment for both large manufacturers and small workshops.</li> </ul> <h2>The Balancing Process with Balanset-1A</h2> <p>The rotor balancing process involves several key steps, from equipment preparation to the installation of corrective weights. Here is a brief overview:</p> <h3>1. Equipment Preparation</h3> <p>Install vibration sensors perpendicular to the rotor's axis of rotation. Attach a laser tachometer to a magnetic stand, directing it at a reflective tape on the pulley. Connect the sensors to the Balanset-1A device and link it to a laptop via USB.</p> <h3>2. Initial Vibration Measurement</h3> <p>Before balancing, weigh a test weight and record its mass and installation radius. Start the rotor and measure the initial vibration level to determine the amplitude and phase of the existing imbalance.</p> <h3>3. Balancing in the First Plane</h3> <p>Place the test weight in the first balancing plane, corresponding to the location of the first sensor. Restart the rotor and measure the vibration level; a change of at least 20% in amplitude or phase indicates partial imbalance correction.</p> <h3>4. Balancing in the Second Plane</h3> <p>Move the test weight to the second plane and repeat the measurement process. This data will enable the software to calculate the precise location and weight of corrective loads needed.</p> <h3>5. Correcting Imbalance</h3> <p>Based on the collected data, the Balanset program will suggest corrective weights and their installation angles. Remove the test weight and prepare the corrective weights as recommended.</p> <h3>6. Verification and Completion</h3> <p>Run the rotor for a final check. If vibration levels have decreased to an acceptable range, the balancing process is complete. The program will indicate if further adjustments are necessary.</p> <h2>Conclusion</h2> <p>The Balanset-1A is a powerful tool for rotor balancing in industrial maintenance. Its ease of use, portability, and high accuracy make it an invaluable asset for technicians seeking to optimize machinery performance and minimize downtime. By investing in the Balanset-1A, you can enhance the reliability of your industrial operations and ensure the longevity of your equipment.</p> <b>Contact Information:</b> For more information about our Balanset balancing devices and other products, please visit our website: https://vibromera.eu. Subscribe to our YouTube channel, where you will find instructional videos and examples of completed work: https://www.youtube.com/@vibromera. Stay updated with our latest news and promotions on Instagram, where we also showcase examples of our work: https://www.instagram.com/vibromera_ou/. <a href="https://www.amazon.ca/dp/B0DCT5CCKT">Buy Balanset-1A on Amazon</a><br> <a href="https://www.etsy.com/listing/1791714976/">Balanset-1A OEM on Etsy</a><br>

LasMujeresPDFspary

¿Todas tus frases empiezan con él...? Necesitas leer esto urgente https://lasmujeresqueamandemasiadopdf.cyou/ robin norwood las mujeres que aman demasiado pdf

bornoftroublepdfspary

Born of Trouble is a masterclass in character development. Witness the growth and evolution of the protagonists in our new pdf edition. This is a story about becoming who you are meant to be despite the obstacles in your way. Start your journey today. https://bornoftroublepdf.site/ Non-Fiction Books Download Free

withthefireonhighpspary

Emoni Santiago is a force of nature in the kitchen and in life. The PDF version of the book captures her energy. With the Fire on High is a story about the fire that drives us to be better to do more and to create something lasting. https://withthefireonhighpdf.site/ With The Fire On High Pdf Online

clapwhenyoulandpdfspary

Acevedos writing is lyrical and moving bringing her characters to life. This novel is a must-read for fans of contemporary fiction. You can access this story by downloading the PDF file. https://clapwhenyoulandpdf.site/ Clap When You Land Vk

isthisacryforhelppspary

The Is This a Cry for Help PDF is perfect for electronic reading. This digital version is convenient. Secure your file now and enjoy. https://isthisacryforhelppdf.site/ Is This A Cry For Help Kindle Paperwhite

MarsvinEvile

I find this forum very interesting. Theres a lot of useful information here.

MarsvinEvile

I find this forum very interesting. Theres a lot of useful information here.

MarsvinEvile

I find this forum very interesting. Theres a lot of useful information here.

MarsvinEvile

I find this forum very interesting. Theres a lot of useful information here.